Dot Dash

This means by ‘tuning’ the size of the QD crystals when they are synthesized, they can be used to convert light of a particular frequency (color) to another color. This differs from phosphors, which typically ‘block’ the light of other colors, with a red phosphor removing the blue and green from a white light and letting only the red light pass. Phosphors therefore reduce the light energy output significantly, while quantum dots ‘shift’ the energy rather than reduce it.

Quantum dots also have other beneficial characteristics, particularly their ‘narrow’ output relative to other materials, which gives them the ability to generate ‘pure’ colors that allow displays to more precisely control the colors that are produced. As quantum dots are ‘stimulated’ by light, they are ideal for QDEF (quantum dot enhancement films) or QDOG (quantum dot on glass) systems that are the basis for many high-end TVs sold today, and have applications where they can replace typical phosphor based color filters in large size LCD and OLED displays, or can be used to convert a single color backlight into an RGB display at a low cost.

But quantum dots have another characteristic that makes them valuable in the display space, and that is not only can they convert the frequency of light that stimulates the QDs, but by applying an electrical charge to the QDs, they can produce light on their own. This self-emissive property is similar to the plasma displays of years ago, where a gas was electrically stimulated to produce a colored dot, or OLED materials that have the same basic property.

Producing quantum dots is a chemical process that must be carefully controlled but is certainly viable for mass production and the move away from cadmium-based quantum dots has reduced or eliminated any question of safety for consumers, with the dots being combined in films or deposited directly on light guides in TV displays. But to use quantum dots effectively for more sophisticated applications, they face the same issues as OLED materials, that of patterning, or precisely placing the dots on the corresponding points in the TFT (thin film transistor) circuitry that controls them. In a 4K display this means over 24m quantum dots have to be correctly placed and in an 8K display just under 100m dots ‘spots’ must align with the TFT electronics.

Small OLED displays are able to use FMM (fine metal masks) to precisely place OLED materials when creating and RGB display, but those masks do not scale to the sizes needed for large OLED TVs, which uses two OLED materials that are coated across the entire display to produce white light, which is then converted to the three primary colors by a color filter. As noted above, the color filter is ‘subtractive’ and reduces the light output of the display, which makes it more difficult for large OLED displays to compete with large LCD displays which tend to be brighter, so the idea of using quantum dots as self-emitting materials would offer a solution to that problem only if the QDs can be patterned across such large displays.

Ink-jet printing is one way that has been tried for patterning self-emissive materials, both OLEDs and quantum dots, but IJP involves dissolving the materials in solvents so they can pass through the ink-jet heads. This can affect the materials, requires ‘curing’ before adjacent materials are deposited, and can add variability to the ink-jet droplets themselves. While IJP is certainly a developing technology that is already used to a degree in the display space, a simpler and less ‘invasive’ process would likely be necessary if self-emissive quantum dots were to surface as a viable commercial display process.

Much research is being conducted on moving quantum dots from ‘converters’ to emitters’, but we have noticed that a group of engineers at a TCL (000100.CH)/Chinastar (pvt) Innovation center have come up with a novel approach to patterning quantum dots that seems to hold promise as a potentially commercial process. The concept uses a process called electrophoretic deposition, which moves particles that are charged to an oppositely charged electrode. Quantum dots can be charged by attaching positive or negative ions to the bonds that attach to the QD core and placing an oppositely charged material in the solution will attract the dots to that material, but that only gets them there en masse.

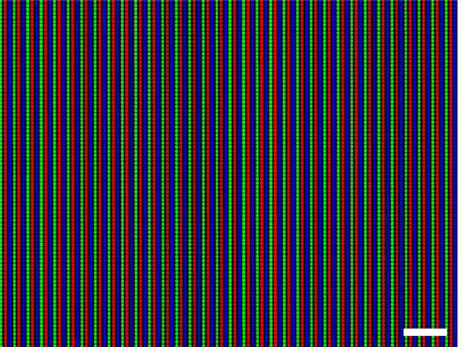

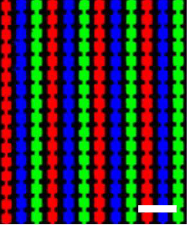

The trick that these researchers came up with is to use photolithography to produce an electrode that is patterned, and will only attract QDs where the pattern exists, similar to the way photolithography is used to produce the circuitry that is the basis for the millions of transistors that appear on semiconductor devices. In the same way, second and third electrode pattern can also be created that would only attract QDs to those locations when turned on, so by charging each electrode only when it is in the proper ‘color’ solution, a complete RGB QD pattern can be created on large substrates, with the thickness of the material controllable by varying the time and strength of the electrical field. In some cases the QDs might be stacked, which would entail simpler patterning and the same three dip process and the process is not limited to rigid substrates opening up the process to flexible and 3D structures. The process (in the lab) took less than a minute for each color with about 20mins drying time for each.

While we don’t often cite lab technology, given the difficulty in transferring much of this kind of work into scalable production, much of this process uses existing technology that is available to display producers or is already part of their process, so it does have some relevance to a working solution that could one day be profitable. The characteristics of quantum dots, particularly their inorganic nature (core) and their color purity make them viable candidates for self-emissive displays and such a more practical process could legitimize the continuing R&D into the development of a realistic Self-emissive QD product timeline.[1]

[1] Zhao, Jinyang. “Large-Area Patterning of Full-Color Quantum Dot Arrays beyond 1000 Pixels per Inch by Selective Electrophoretic Deposition.” Nature Communications.

RSS Feed

RSS Feed